WhatsApp: +86 180 3242 3029

sales@qunkun.net

创始人2022-10-19 15:46:02

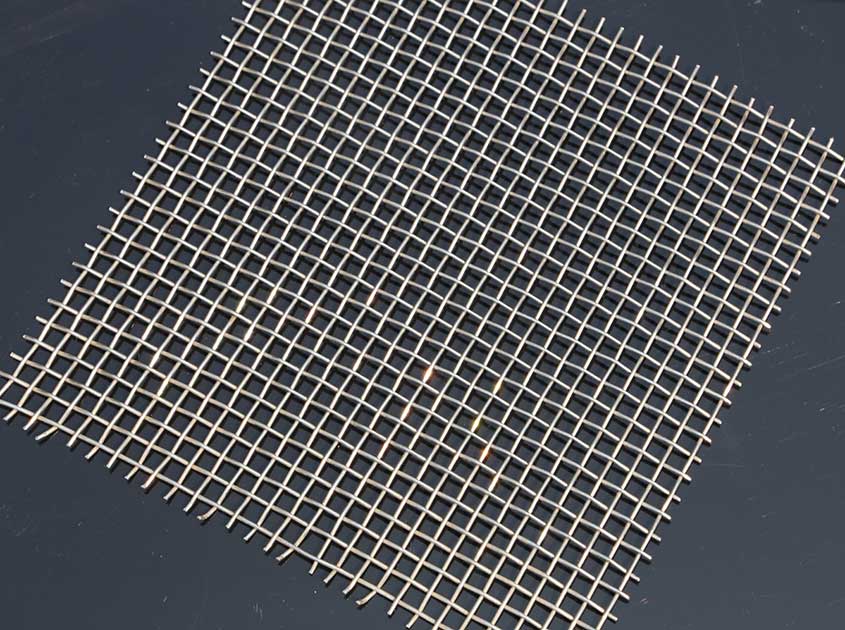

Features of wire mesh corrugated packing:

Wire mesh corrugated packing (the corrugated top angle is about 90 degrees, and the channel formed by the corrugation is 45 degrees or 30 degrees to the vertical direction. The flow channels of two adjacent corrugated sheets are at 90 degrees, and the upper and lower disks of corrugated packing are rotated 90 degrees and stacked. In a tower with a smaller diameter connected by a flange, the corrugated packing is made into a whole disk, and the diameter is slightly smaller than the inner diameter of the tower. In a tower with a larger diameter, each disk of corrugated packing is divided into several pieces, which are put into the tower through the manhole Inside the tower, they are assembled into complete disks, and the corrugated sheets of the upper and lower disks are rotated 90 degrees to make the fluid fully mixed in the tower. It has thin walls, large void ratio, large flux, and light weight. The resistance is small, the inclination angle of the gas phase passage is small, regular, the gas contact is sufficient, the separation effect is good, the high efficiency, the pressure drop and other characteristics,

Application of wire mesh corrugated packing:

Wire mesh corrugated packing (stainless steel corrugated packing) is the most widely used high-efficiency packing around the world, especially suitable for vacuum distillation column. Mainly used in petrochemical industry, fertilizer industry, natural gas purification, smelting, etc. Such as coal chemical industry (benzene washing tower for recovering crude benzene in coking plant), ethyl styrene separation, high-purity oxygen production, propylene oxide separation, debutanizer, cyclohexane recovery, gasoline fractionation, atmospheric and vacuum oil refining and other devices Medium as etc. For example, it is used in three-phase separator or two-phase separator packing in crude oil degassing and dehydration treatment. Xtep is suitable for handling materials that are heat-sensitive, easy to decompose, easy to polymerize, and easy to carbonize.

© 2024 Qunkun Metal. All Rights Reserved.