WhatsApp: +86 180 3242 3029

sales@qunkun.net

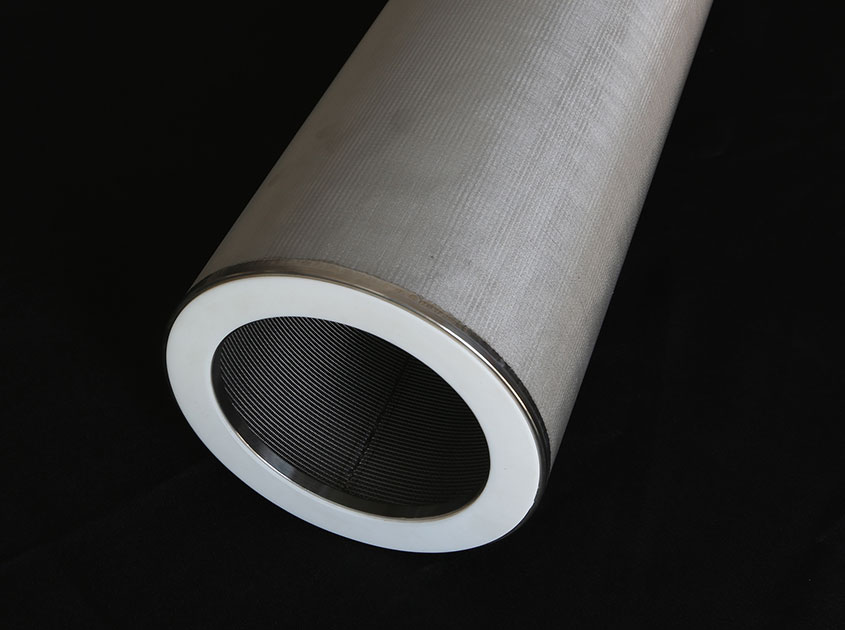

Sintered metal Mesh is a wire filtering cloth made by pressing multi-layer stainless steel woven wire cloth then sintered together in vacuum furnace. this creates a unique material offering excellent mechanical properties. it is ideal material for purification and filtration.This kind of filtering cloth is much better than common metal woven wire mesh with good strength hardness and good positioning of opening. the multi-layer sintered mesh is superior to common metal mesh for offering higher durability strength hardness and good position of pores. sintered mesh offers high flow rates with average loadings and features adequate cleaning and backwash properties.

The main technology of sintered mesh filter is that a large number of high-precision welding processes are adopted. The sintered mesh filter is welded after the treatment of rolling circle the welding joint shall be fixed after making sure the roundness to be welded well it makes the products looks more nice . Sintered mesh is a kind of porous sintered material which is made of stainless steel wire mesh stacked together according to different structures and then made by sintering pressure rolling and other processes. Due to its surface filtration mechanism and smooth mesh channels it has excellent washability and regeneration performance and can be used repeatedly for a long time especially suitable for continuous and automatic operation process which is incomparable to any filter material.

Sintered filter is generally divided into 5 layers including protection layer filter layer and reinforcement mesh. This product not only has stable filtration precision but also has high strength and rigidity. It is suitable for the filtration environment with high pressure resistance and uniform filtration strength. It is a new ideal filtration material.

1. Polymer filtration and polyester melt purification.such as polyaramides polyesters polypropylene polyamide Nylon.

2.Viscose rayon filtering.

3.Filtration of powders and trapping particulates from vacuum and compressed air lines.

4. Filtration of refining process pre-filtration of ultrafilter.

5. Electronic high temperature gas dust removal.

6. Liquid purification in pharmaceutical petroleum biology and beverage industries.

7. Vacuum pump protection filter filter membrane support Catalyst filter media.

8. Airbags of cars and fuel filtration of aircraft and ships.

9. Hydraulic system filtration

Features of Sintered Filter

Technical Details

|

Filter Rating (u) |

Protection layer |

Protection layer |

Filter layer |

Reinforcement Mesh |

Reinforcement Mesh |

Thickness (mm) |

Permeability (L/min/cm2) |

|---|---|---|---|---|---|---|---|

| 1 | 200 | 400x3000 | 200 | 12x64 | 64x12 | 1.7 | 1.81 |

| 2 | 100 | 325x2300 | 100 | 12x64 | 64x12 | 1.7 | 2.35 |

| 5 | 100 | 200x1400 | 100 | 12x64 | 64x12 | 1.7 | 2.42 |

| 10 | 100 | 165x1400 | 100 | 12x64 | 64x12 | 1.7 | 3.00 |

| 15 | 100 | 165x1200 | 100 | 12x64 | 64x12 | 1.7 | 3.41 |

| 20 | 100 | 165x800 | 100 | 12x64 | 64x12 | 1.7 | 4.50 |

| 25 | 100 | 165x600 | 100 | 12x64 | 64x12 | 1.7 | 6.12 |

| 30 | 100 | 400 | 100 | 12x64 | 64x12 | 1.7 | 6.86 |

| 40 | 100 | 325 | 100 | 12x64 | 64x12 | 1.7 | 7.10 |

| 50 | 100 | 250 | 100 | 12x64 | 64x12 | 1.7 | 8.41 |

| 75 | 100 | 200 | 100 | 12x64 | 64x12 | 1.7 | 8.70 |

| 100 | 100 | 150 | 100 | 12x64 | 64x12 | 1.7 | 9.10 |

| 150 | 50+100+50+30+30+100+50 | 2.0 | 25.00 | ||||

| 200 | 40+80+40+20+40+80+40 | 2.0 | 26.00 | ||||

The different ways in which our products are packed are:

We mark Duplex 2205 as needed with the most suitable & visible marking techniques. Standard Marking System :-

Get Best Quotes or Send us your Requirement

© 2024 Qunkun Metal. All Rights Reserved.